Finding your suitable readers for wood veneer sample packs is not easy. You may need consider between hundred or thousand products from many store. In this article, we make a short list of the best readers for wood veneer sample packs including detail information and customer reviews. Let’s find out which is your favorite one.

556 reviews analysed

1. Wood Identification Kit

2. Veneer Variety Pack 20 Sq. Ft. by Sauers

Description

For inlays, marquetry and small veneering projects, as well as project planning and working with clients to pick a wood species, our 20-Square-Foot Veneer Variety Pack is an ideal sampler platter of the best premium veneers available. Veneer sheet sizes range from 4-1/2″ to 6-1/2″W x 12″L, the perfect size for jewelry boxes, humidors, door panels, marquetry and more. Contents of the variety pack may vary, but will include a mix of domestic and exotic veneers. All veneer sheets boast straight, parallel edges, and are free of defects, so there’s no waste. Sheet count will vary to make up 20 square feet, but will generally be around 40 sheets of veneer.

Technical Details:

The Veneer Variety Pack is ideal for marquetry, inlay and small veneering projects.

Includes a range of domestic and exotic veneers.

Veneer sheet sizes range from 4-1/2″ to 6-1/2″W x 12″L.

Sheet count will vary to make up 20 square feet.

Sold in packs of 20 square feet (about 40 sheets).

What’s in the Box?

(20) Square Feet of Mixed Solid Wood Veneer

3. Poplar one side Maple one side wood veneer sample sheet 10" x 8" x 1/32" thick

Description

Poplar one side Maple one side all wood veneer 10 x 8 1/32 thickness. A grade quality. All pieces similar.

Trust the experience, knowledge, and reputation that has served the wood industry and novices since 1995.

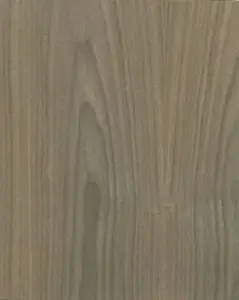

About pictures: Most pictures have been temporarily wet on the lower portion of the veneer to show what the grain may look like when finish is added. Color adjustments have been made to show the color as best as is possible. It is impossible to get photos exactly correct in color, but we have made an effort to do so.

Backed products come with complete application instructions that are simple and clear. For raw veneer or un-backed products, we suggest using the Internet to see what advice is available as opinions vary on the best way to handle that product. Below is general information for most of our products. Make sure you check the listing to see which applies to the above product in particular.

Thickness: (will not always be exactly correct, but relatively close)

Paper-backed veneers = 1/40”

Wood-backed veneers = 1/25”

Raw plain veneer with no backing = 1/32”-1/42”

Exported By ExportYourStore

4. Cherry, Flat Cut, 24×96 10 mil(Paperback) Wood Veneer Sheet

Feature

- Unfinished, Ready for stain and finish, Veneer provides stability and flexibilty while helping to minimize splitting, grain-raise and glue seepage

- Grain and Color appearance variation can be expected from sheet to sheet and lot to lot, it will vary from what is pictured because it is a natural wood product

- Wraps up to 1″ radius, 10 mil(Paperback) (Overall Thickness .024+/- .010)

- Great for refacing, refurbishing, and repairing furniture, shelves, cabinets,

- Used for Wall panels, Doors, Tables, Cabinets

5. Red Oak Wood Veneer Flat Cut, 10 mil 24×96 Sheet A Grade

Feature

- Unfinished, Ready for stain and finish, Veneer provides stability and flexibilty while helping to minimize splitting, grain-raise and glue seepage

- Grain and Color appearance variation can be expected from sheet to sheet and lot to lot, it will vary from what is pictured because it is a natural wood product

- Wraps up to 1″ radius, 10 mil(Paperback) (Overall Thickness .024+/- .010)

- Great for refacing, refurbishing, and repairing furniture, shelves, cabinets,

- Used for Wall panels, Doors, Tables, Cabinets

6. Maple Wood Veneer Rotary Spliced 2’x8′ 10 mil Sheet

Feature

- 2’x8′ Unfinished Maple Rotary Spliced, Ready for stain and finish

- Grain and Color appearance variation can be expected from sheet to sheet and lot to lot, it will vary from what is pictured because it is a natural wood product

- Great for refacing, refurbishing, and repairing furniture, shelves, cabinets,

- Wraps up to 1″ radius, 10 mil(Paperback) (Overall Thickness .024”+/- .010)

Description

White Oak Rift Cut Wood Veneer A Grade 2’x8′ 10 mil(Paperback) (Overall Thickness .024”+/- .010) The 10 mil paper backed veneer provides stability and flexibility while helping to minimize splitting, grain-raise and glue seepage. Tenderized Paperback veneer will bend to wrap a 1″ radius. Grain and Color appearance variation can be expected from sheet to sheet and lot to lot, it will vary from what is pictured because it is a natural wood product. Solvent-Based adhesive is recommended. Water based adhesives are not recommended. Adhesives should be allowed to cure for 48 hours prior to finishing. Ready for light stain and/or clear finish. Great for refacing, refurbishing, and repairing furniture, shelves, cabinets, ect. All veneer should be acclimated prior to application. Surface must be clean, dry and smooth to ensure a good bond. Machine Surface Sand of 150 grit. Veneer is sanded to a smooth uniform finish. Application instructions included with material.

7. Walnut Wood Veneer Flat Cut, 24×96 PSA 9505 Sheet

Feature

- Unfinished, Ready for stain and finish, Veneer provides stability and flexibilty while helping to minimize splitting, grain-raise and glue seepage

- Grain and Color appearance variation can be expected from sheet to sheet and lot to lot, it will vary from what is pictured because it is a natural wood product

- Wraps up to 1″ radius, 10 mil(Paperback) (Overall Thickness .024+/- .010)

- Great for refacing, refurbishing, and repairing furniture, shelves, cabinets,

- Used for Wall panels, Doors, Tables, Cabinets

Description

PSA provides a simple, easy alternative to apply veneer without the need to use a secondary adhesive. Our 3M peel & stick is the perfect choice for cabinet refacing for hobbyists and professionals.

8. Arc Crafts BARC Wood Sheet W/Adhesive Backing 12"X12", White Birch

Description

Arc Crafts-BARC Wood Sheet With Adhesive Backing: White Birch. BARC wood products cut well with scissors die cutters rotary cutters plotters and punches. They can be printed with offset letterpress flexo silk screen inkjet and digital. BARC wood products are versatile and have unlimited applications for card making scrapbooking invitations painting albums staining rubber stamping foil stamping laser cutting embossing debossing and hot glue application. This package contains one 12×12 inch sheet of BARC wood with adhesive backing. Made in USA.

9. Maple, White, Flat Cut, 24×96 10 mil (Paperback) Wood Veneer Sheet

Feature

- Unfinished, Ready for stain and finish, Veneer provides stability and flexibilty while helping to minimize splitting, grain-raise and glue seepage

- Grain and Color appearance variation can be expected from sheet to sheet and lot to lot, it will vary from what is pictured because it is a natural wood product

- Wraps up to 1″ radius, 10 mil(Paperback) (Overall Thickness .024+/- .010)

- Great for refacing, refurbishing, and repairing furniture, shelves, cabinets,

- Used for Wall panels, Doors, Tables, Cabinets

Description

Maple Wood Veneer Plain Sliced 2’x8′ 10 mil (Paperback) (Overall Thickness .024+/- .010) The 10 mil paper backed veneer provides stability and flexibility while helping to minimize splitting, grain-raise and glue seepage. Tenderized Paperback veneer will bend to wrap a 1″ radius. Grain and Color appearance variation can be expected from sheet to sheet and lot to lot, it will vary from what is pictured because it is a natural wood product. Solvent-Based adhesive is recommended. Water based adhesives are not recommended. Adhesives should be allowed to cure for 48 hours prior to finishing. Ready for light stain and/or clear finish. Great for refacing, refurbishing, and repairing furniture, shelves, cabinets, ect. All veneer should be acclimated prior to application. Surface must be clean, dry and smooth to ensure a good bond. Machine Surface Sand of 150 grit. Veneer is sanded to a smooth uniform finish. Application instructions included with material.

Conclusion

By our suggestions above, we hope that you can found Wood Veneer Sample Packs for you.Please don’t forget to share your experience by comment in this post. Thank you!